How to Make Carrot & Lemongrass Cold Process Soap

INFORMATION

- Difficulty: Beginner

- Yield: 8 Bars

TIMING

- Prep Time: 30 Minutes

- Perform Time: 1 Hour, 15 Minutes

- Total Time: 1 Hour, 45 Minutes (longer if putting through gel, which is recommended)

- Cure Time: 4-6 Weeks

SUPPLIES

- Goggles

- Extra Long Disposable Nitrile Gloves (easily found in dishwashing section at local supermarket)

- Digital Scale

- Digital Thermometer or Infrared Thermometer

- Stick Blender

- Mini Cordless Mixer (optional)

- 2 Quart Glass Mixing Bowl or Microwavable Plastic Bowl

- 2 x Funnel Pitchers

- Small Containers (for holding ingredients)

- Spatula

- Pipettes

- Measuring Spoons

- Fine Mesh Strainer (Stainless Steel)

- Paper Towels

- 8” Tall & Skinny Silicone Loaf Mold (If you don’t have this mold you can make your own. Click Here to see our tutorial on how to make your own mold out of a cereal box.)

- Heating Pad (Optional)

- Timer (Optional)

- Cardboard Box That Fits over Mold (Optional)

- Towels/Blankets

- Vegetable Peeler (Optional)

INGREDIENTS

- 8 oz Olive Oil (30%)

- 8 oz Palm Oil, Melted (30%)

- 6.7 oz Coconut Oil (25%)

- 2.7 oz Cocoa Butter (10%)

- 1.3 oz Castor Oil (5%)

- 2.9 oz Carrot Puree (baby food is easier and cheaper) or Carrot Juice (in refrigerated section at supermarket) *If you want less of an orange color, use less carrot and more distilled water as long as the weight adds up to 6.7 oz. total between to two ingredients.

- 1.7 oz Lemongrass Essential Oil, Sweet (10%)

- 1.5 teaspoons White Kaolin Clay (0.9 teaspoon per pound of oils)

- 3.8 oz Cold Distilled Water (1:1 Water:Lye ratio) (when the carrot is added, the liquid content will be 25%, so if you are putting this recipe into SoapCalc©, use 25% for “Water as a percentage of oil weight”)

- 3.8 oz Sodium Hydroxide (Lye) (6% Super Fat/Lye discount)

DIRECTIONS

Before starting this tutorial please make sure and read all instructions.

You should have a basic understanding of making Cold Process Soap before you begin this tutorial.

Now put on your long sleeves, long pants, shoes, safety goggles, and gloves. Work in a well ventilated area that is free from distractions.

Step 1 – Measure All Ingredients

To make the process go faster, measure all ingredients first. To cut down on dishes, measure cold water into the funnel pitcher and measure coconut oil into the large mixing bowl. Measure sodium hydroxide last.

Step 2 – Make Lye Solution

Sprinkle around half of the sodium hydroxide into the cold water, stir gently to avoid splashing. Make sure to avoid breathing any fumes. Repeat, and stir until mixture is dissolved; always add lye to water and not the other way around. Set aside in a safe place to cool.

Step 3 – Make Oil Solution

Melt coconut oil in 30 second bursts until completely melted.

Next, add cocoa butter to the melted coconut oil. Stir to melt completely or microwave in 30 second bursts if needed, then set aside.

Step 4 – Combine Olive Oil, Clay and Essential Oil

Add kaolin clay to olive oil. Make sure mini mixer is totally immersed, stir a bit and then blend until incorporated. In order to try not to introduce air bubbles into the mixture, keep the blending tip immersed at all times. Next, add the lemongrass essential oil and mix until incorporated.

Step 5 – Finish Making Oil Solution

If you want to gel your soap, now is a good time to turn on your heating pad.

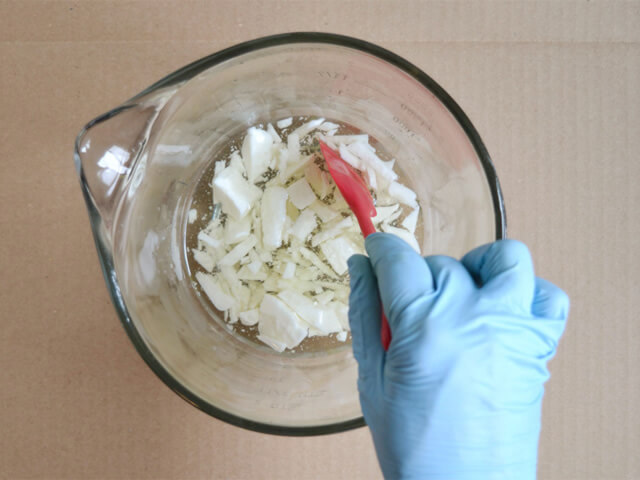

Add the olive oil, clay, and essential oil mixture to the large mixing bowl with the melted coconut oil and cocoa butter. Next, add the melted palm oil, castor oil, and carrot puree/juice. Stick blend to incorporate.

Quick Tip: Pour ingredients down the side of the bowl or down a spatula to avoid adding air bubbles to the mixture.

Step 6 – Make Soap

When the temperatures of the lye solution and the oil solution are within 80°- 85° F, carefully (with safety gear still on) strain the lye solution into the other funnel pitcher. Use paper towels to wipe strainer and empty pitcher.

Next, pour the strained lye solution into the oils, pouring down the side of the container. Before turning it on, insert stick blender at an angle to the bottom and shake it a bit to release any trapped air. Then, blend in short bursts until medium trace is reached (a thin pudding consistency.)

Step 7 – Pour the Batter

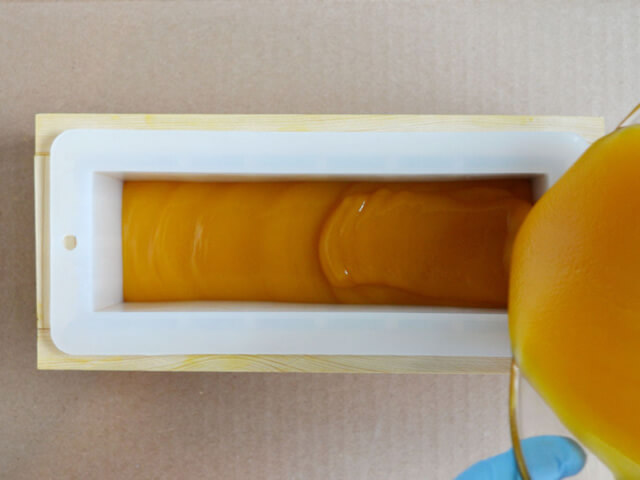

Pour batter into aTall & Skinny Silicone Loaf Mold as shown. (If you don’t have a mold on hand, make your own! Click Here to see our tutorial on how to make your own mold out of a cereal box.) Once the batter is poured bang mold on counter to release any trapped air.

Step 8 – Put Through Gel*

Next, set your mold on top of the heating pad. Then, cover with a box. Next, insulate with blankets/towels. Set your timer for 20 minutes. When the timer rings, slide your hand up under the box and feel the air. If the air is warm, turn off the heating pad. If it’s not warm, keep repeating in 20 minute increments until the air in the box feels warm, then turn off the heating pad. At this point, make sure the mold is snug and keep it covered for at least 48 hours. (The sooner the soap is exposed to air, the more likely it is to develop soda ash.) Ambient temperature matters as well. If your home is warm you probably won’t need the heating pad.

*You don’t have to put your soap through gel; you will get soap no matter if it goes through gel or not. This soap is made with a water discount to prevent glycerin rivers. With less water, soap goes through gel phase faster, often causing partial gel. That’s why it often needs to be forced through gel. Other benefits of forcing soap through gel is that it releases from the mold easier, it is harder, cures faster & lasts longer, the colors are often more brilliant, and it avoids partial gel.

Step 9 – Unmold and Cut Soap

If the soap releases from the mold easily without sticking to the sides, it’s ready to unmold. If not, cover and let it sit until it’s ready. (It doesn’t pay to rush unmolding.)

Mark your soap top and cut it into 8 pieces.

You can wait a day and bevel the edges with a vegetable peeler if desired. Finally, allow them to cure for 4-6 weeks and Enjoy!

SHARE ON SOCIAL MEDIA

![]() Share this tutorial on Facebook

Share this tutorial on Facebook![]() Tweet about this tutorial

Tweet about this tutorial