How to Make Hot Process Shaving Soap

This shaving soap, made with lots of moisturizing shea and cocoa butter, works up into a thick, creamy lather almost instantly, giving a smooth, comfortable shave. Shaving soaps differ from regular soaps in a couple of ways. This soap is made with both sodium hydroxide and potassium hydroxide, making it softer than bar soap (40% and 60%, respectively). This softness makes it faster to build up lather. Shaving soaps have an interesting fatty acid profile compared to a traditional bar soap. This soap has 40% stearic acid in it from shea butter, cocoa butter, palm oil and pure stearic acid. This makes the lather of this soap thicker, more stable and creamier. Perfect for shaving!

This soap is scented with a cool combination of peppermint and patchouli essential oils. You can substitute an equal weight of any essential oil or your favorite fragrance oil. We carry many Masculine Fragrance Oils that the men in your life are sure to love!

After the cook, this shaving soap has glycerin and yogurt stirred into it. Glycerin makes the soap softer and is a wonderful humectant for the skin. In addition to being a good skin conditioner, yogurt contains lactic acid which makes the soap more fluid and easier to pour. You can substitute 1¼ teaspoons of 60% sodium lactate solution, if you prefer.

This soap is made in a 6 quart slow cooker. You can comfortably double or triple this batch, but do not go beyond that unless you have a larger cooker. If you want to halve this batch, you should also use a smaller cooker because the level of soap will be too low to easily stick blend.

This soap has a 6:1 ratio of water to lye and 8% superfat.

INFORMATION

- Difficulty: Advanced

- Yield: 6 x 8 oz jars, each with 4.4 oz / 125 g product, by weight

TIMING

- Prep Time / Clean Up: 25 Minutes

- Perform Time: 1 Hour, 45 Minutes

- Total Time: 2 Hours, 10 Minutes

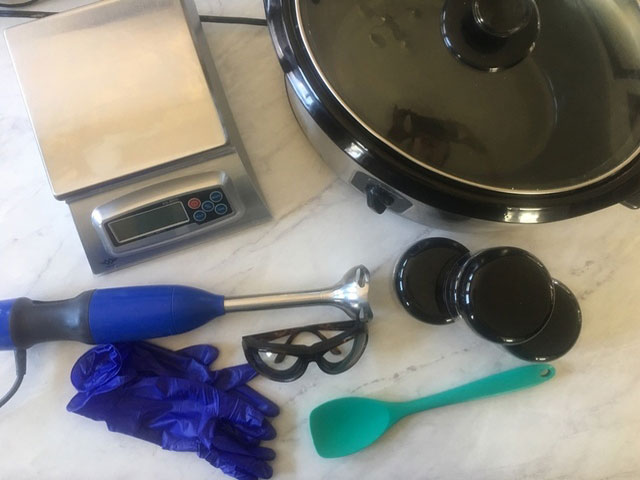

SUPPLIES

- Digital Scale

- 6 qt Slow Cooker

- Immersion Blender

- Goggles

- Funnel Pitcher

- Latex or Nitrile Gloves

- Digital Thermometer

- Silicone Spatula

- Pipettes (for essential oil)

- Paper Towels

- Timer

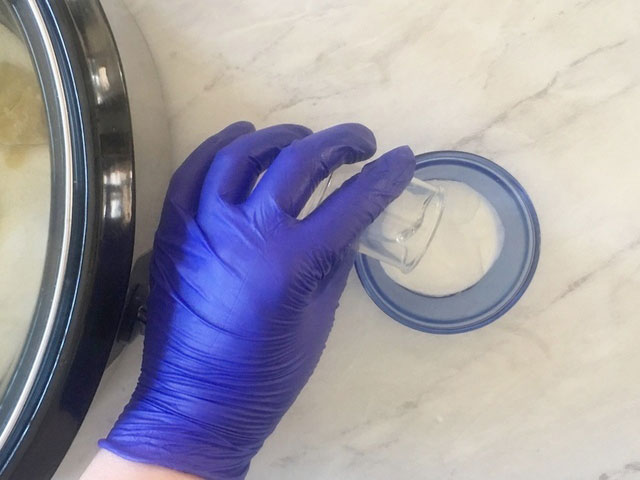

- Small glass bowl or cup

- 6 x 8 oz Plastic Jars

- 6 x Black Dome Lids

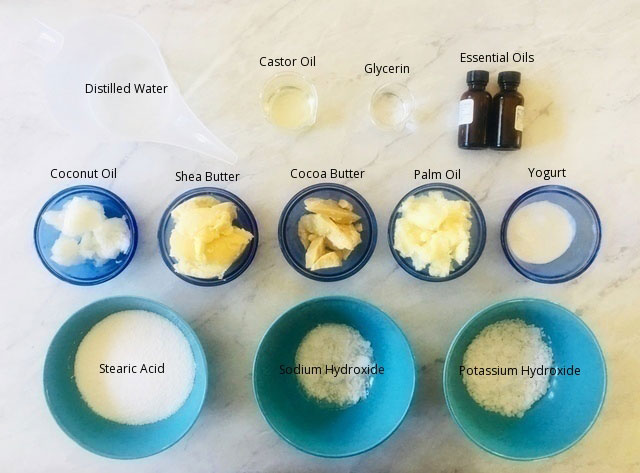

INGREDIENTS

- 5 oz / 141.7 g Stearic Acid (25% of oils)

- 5 oz / 141.7 g Shea Butter (25% of oils)

- 4 oz / 113.4 g Palm Oil (20% of oils)

- 3 oz / 85 g Coconut Oil (15% of oils)

- 2 oz / 56.7 g Cocoa Butter (10% of oils)

- 1 oz / 28.3 g Castor Oil (5% of oils)

- 1.05 oz / 29.9 g Sodium Hydroxide (NaOH)

- 2.47 oz / 69.9 g Potassium Hydroxide (KOH), 90% Purity

- 17.6 oz / 499 g Distilled or Deionized Water

- 1 oz / 28.3 g Glycerin (Available from Pharmacies)

- 0.75 oz / 21.26 g Plain Yogurt, Any Fat Percentage (Greek Yogurt or Regular)

- 0.5 oz / 14.17 g Peppermint Essential Oil

- 0.1 oz / 2.83 g Patchouli Essential Oil

DIRECTIONS

Before starting this tutorial please make sure to read all instructions. Wear safety goggles, closed-toed shoes, long sleeves, long pants and gloves when working with lye or raw soap. Make sure there are no small children or pets in the room and that you are undistracted. Make your lye solution in a stainless steel or polypropylene container, such as a Funnel Pitcher. Do not use glass or another kind of plastic. Use caution when handling heated oils. Use disposable pipets when dispensing essential oils. Do not place undiluted essential oils in plastic ware. Carefully weigh all ingredients and gather your equipment before you start working.

It’s always a good idea to run a new soap recipe through a lye calculator. You will need to use one that accommodates dual lye such as the one found at http://soapcalc.net/calc/SoapCalcWP.asp.

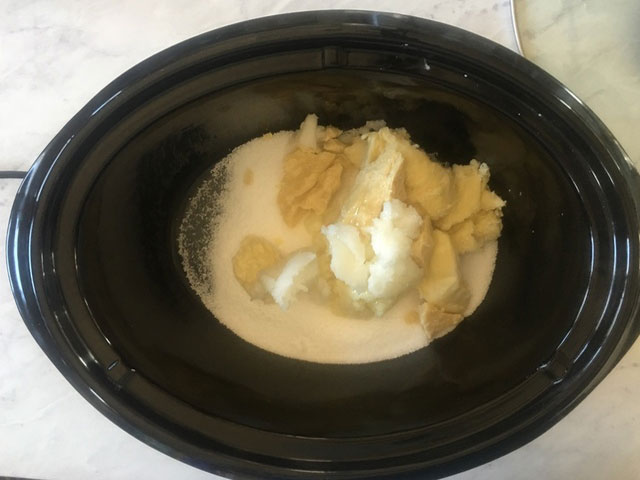

Step 1 – Melt the Butters and Oils

Combine the stearic acid, shea butter, palm oil, coconut oil, cocoa butter, and castor oil in your slow cooker. Turn the cooker on to high and allow your oils to melt completely. This will take about 30-40 minutes depending on how hot your slow cooker is. Stearic acid takes a long time to melt, so be patient!

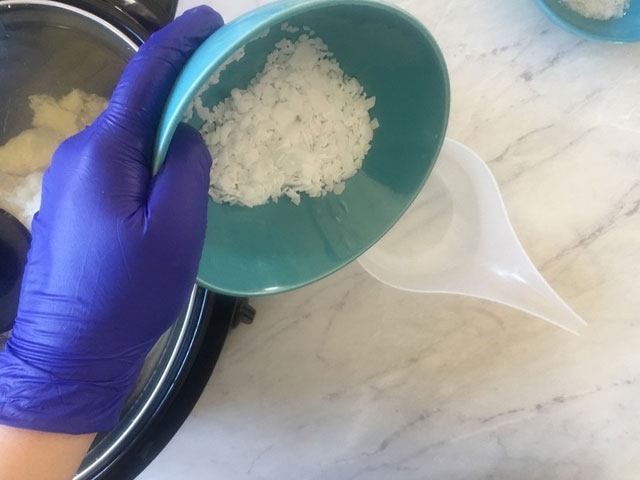

While your oils melt, add the potassium hydroxide and sodium hydroxide into the distilled water in a funnel pitcher. Work in a well-ventilated area. Stir until dissolved. (Note: add the lye to the water, not the water to the lye. The mixture will get quite hot!)

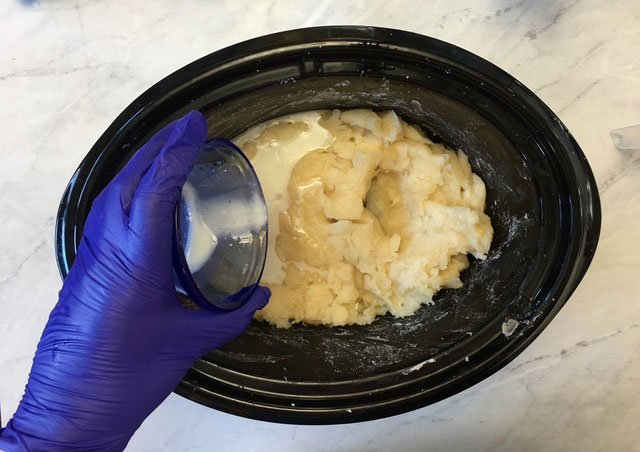

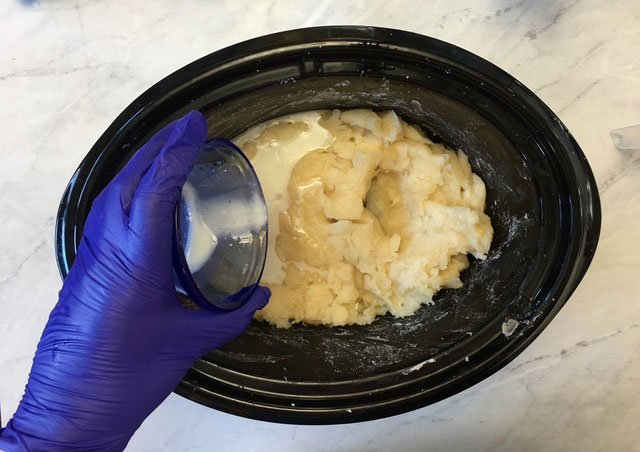

Combine the essential oils, glycerin, and yogurt in a small glass bowl or cup.

Step 2 – Bring the Soap to Trace

Pour the lye solution into the oils.

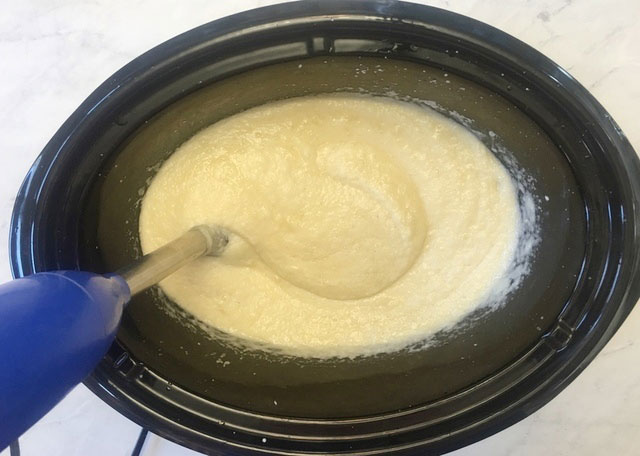

Stick blend on high. The mixture will seize up into an applesauce consistency.

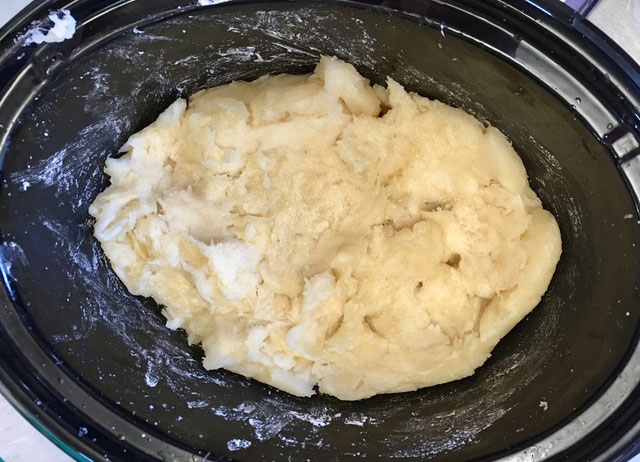

After a couple minutes, the mixture will have the texture of soft mashed potatoes.

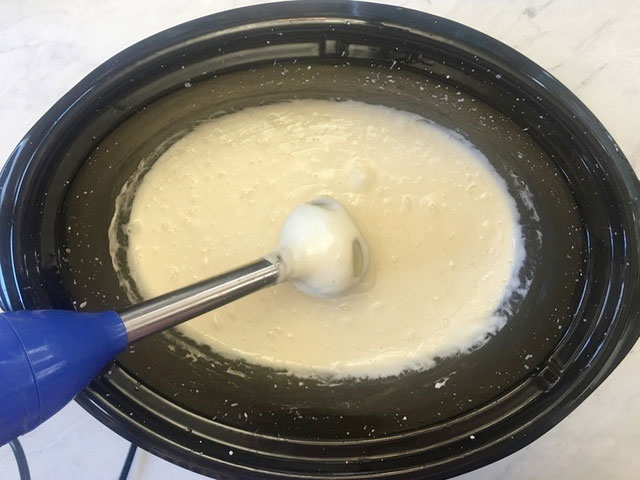

After about 10 minutes of stick blending, the mixture will smooth out and have the appearance of cake mix batter. The soap base is now at trace.

Step 3 – Cook the Soap Base

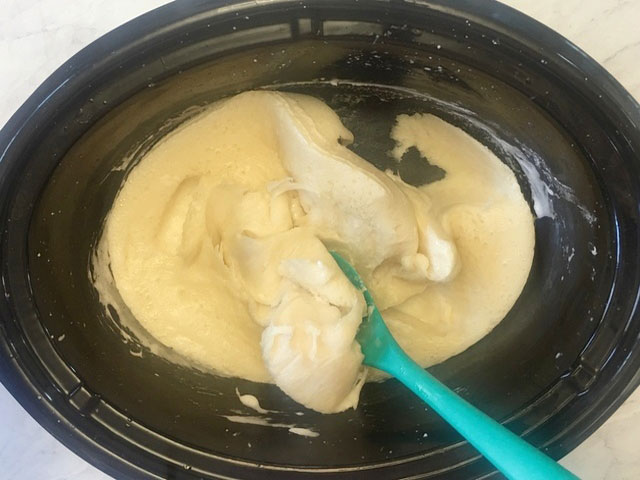

Cover the soap and cook on high for 45-60 minutes, stirring every 20 minutes. To stir the soap, use the spatula to fold the soap to stir it. The soap will be a very thick paste, so just do your best to stir it.

When the soap takes on a glossy, slightly translucent condition, test the soap for doneness. The easiest way to test the soap is to take a tiny bit of the soap on a small spoon and place it on your tongue. Undercooked soap will “zap” your tongue like a battery. Cooked soap will just taste slightly bitter. Alternatively, you can test the soap with phenolphthalein drops or a pH Meter by taking 1g of the soap and dissolving it in 99g of distilled water and inserting the probe. The soap will have a pH at or below 10.

Step 4 – Finish the Soap

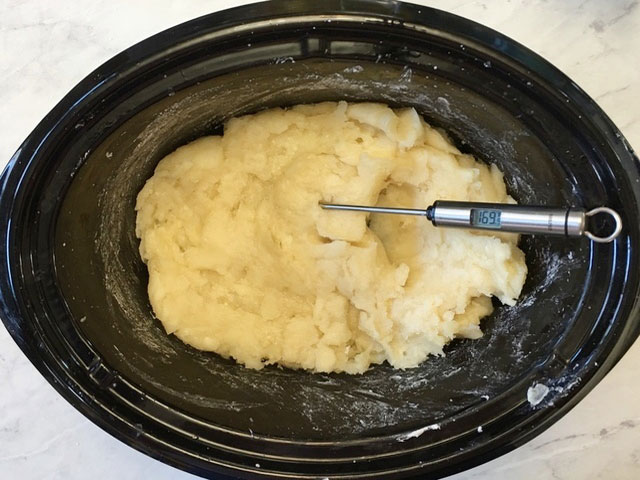

Turn off the slow cooker. Allow the soap to cool to 175o, or below.

Stir in the yogurt mixture. The soap will loosen up a little.

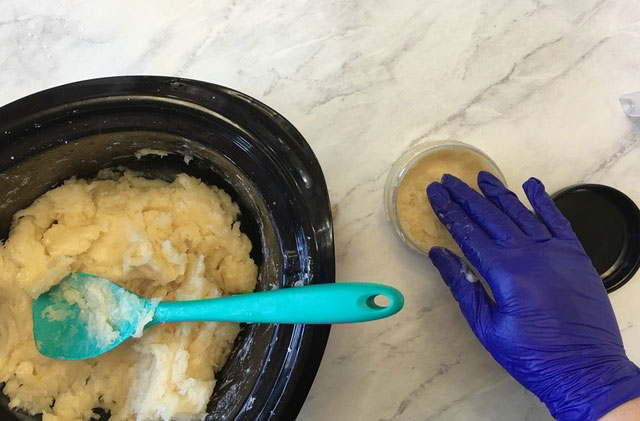

Working quickly, spoon the soap into each of the jars.

Use your hand to firmly press the soap into each of the jars, removing as many air bubbles as you can.

Smooth out the top of each jar using a spatula.

Clean off the outside of each jar with a damp paper towel. Keep the soaps uncovered for 48 hours to allow them to dry out. The soaps are safe to use right away, but will last longer if you let them cure for a couple of weeks.

To use, wet a shaving brush with warm water. Swirl the brush across the top of the soap to build a thick lather. You are now ready to shave!

PDF DOWNLOAD FOR YOUR CONVENIENCE

SHARE ON SOCIAL MEDIA

![]() Share this tutorial on Facebook

Share this tutorial on Facebook![]() Tweet about this tutorial

Tweet about this tutorial